What Is Wasted Motion Costing Your Warehouse?

It’s important to constantly study warehouse processes and work to find the most efficient way of completing essential tasks. Small efficiencies can make or break a business as they add up to high costs and squandered time.

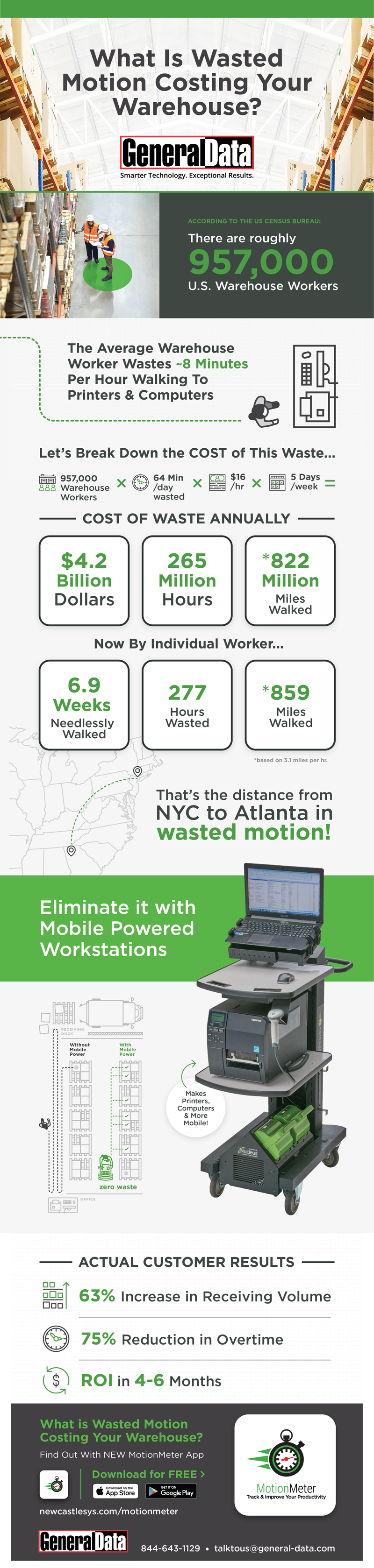

This infographic shows the significance and impact of wasted motion by the numbers:

Want to download a copy of this infographic? Get it here.

A Warehouse Game Changer

Mobile powered workstations improve speed, capacity, infrastructure costs and employee productivity allowing you to fully leverage your wireless facility by cutting the power cords and letting your workstations move to where they are needed - with your people. Adding mobility to your shop floor opens a floodgate of opportunities to improve processes even further. General Data provides mobile powered workstations to distribution, shipping/receiving, production and healthcare facilities. As General Data is a premier partner with the industry's top mobile powered workstation manufacturers, we can help you find the right mobile workstation to meet the demands of your business.

Contact General Data today to learn more about how mobile powered workstations can improve your warehouse processes.