The scannability - or more specifically, the “decodability” - of a barcode depends on a number of factors, but one of the primary factors is how it is printed. Different print methods can produce very different results depending on the what type of barcode is being printed, at what size, on what surface, and what barcode reader is being used for scanning.

In the histology lab, the type of barcode that is primarily used to identify cassettes is the Data Matrix barcode. This two-dimensional barcode uses a series of black and white cells arranged in a square or rectangular pattern. A white cell represents a “0” and a black cell represents a “1”. There are also two solid borders in an “L” shape, and two other borders of alternating black and white cells. The barcode reader decodes the matrix of these black (dark) and white (light) cells to produce the data that is encoded in the matrix.

Data Matrix barcode

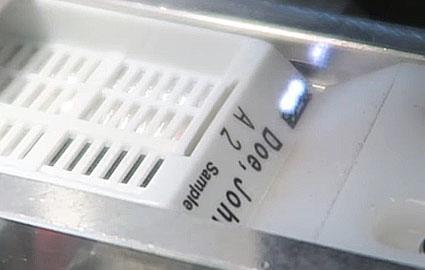

Depending on the size of the Data Matrix barcode and the amount of data stored in it, the barcodes can become quite dense and the size of the cells very small. For tissue and biopsy cassettes, the barcodes are primarily printed on the face of the cassette – an area usually no larger than 5 mm high. This Data Matrix barcode needs to hold up to 16 characters. This results in a very small, dense barcode containing a lot of very small cells.

In order for a barcode reader to decode these very small Data Matrix barcodes printed on the face of a biopsy or tissue cassette, the barcode must have two characteristics: (1) sufficient contrast, and (2) proportionally correct dark and light cells with clean, sharp edges. Otherwise the barcode won’t scan.

To obtain these decoding characteristics, you must use a printing technology that is designed to print very small images on histology cassettes with a high degree of precision. There is only one printing technology that can consistently create these small, dense barcodes that will scan and decode consistently: LASER.

Why is laser the preffered printing technology for printing on cassettes? Let’s take a quick look at the other printing technologies commonly used to print on cassettes:

- Inkjet - Inkjet involves “spraying” ink on the surface of the cassette to create the barcode. There are numerous problems with this when creating small, dense barcodes, including ink splatter, light cells filling in from overspray, and not being able to create sharp, defined lines and edges. In addition, ink nozzles can clog, and require cleaning.

- Impact - These printers have small pins that punch against the back of a ribbon or tape to transfer the ink from the ribbon/tape in a series of dots to the surface of the cassette to create the barcode. This method can produce inconsistent print contrast. In addition, it is virtually impossible to use printed dots to create straight, sharp lines and edges. As a result, the decodability of these barcodes is generally poor.

- Thermal Transfer - Thermal transfer printing uses heat to transfer the ink from a thermal transfer ribbon to the surface of the cassette to produce the barcode. This is the printing technology most commonly used to print barcode shipping labels in industrial settings, and slide labels in labs. However, printing a small, dense Data Matrix barcode on a cassette is a very different thing. This requires a high-resolution (expensive) printhead with a high dpi capability that will need to be replaced on a regular basis.

Laser technology uses a highly concentrated and focused beam of light to “draw” the Data Matrix barcode on the surface of the cassette. It produces razor-sharp edges with a high degree of contrast between the dark and light cells within the barcode. The cells are in correct proportion, even within the small and dense Data Matrix barcode that a tissue or biopsy cassette requires. That’s why users report nearly perfect scan rates when scanning barcodes on cassettes printed with laser technology.

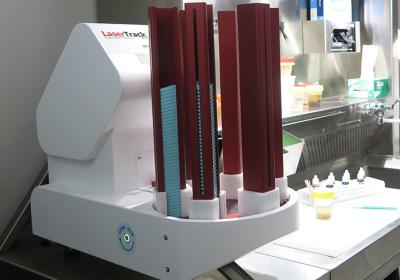

In addition, laser technology has no ribbons, tapes, ink or printheads to replace, and no clogged inkjet nozzles to clean. For all these reasons, LaserTrack Cassette Printers are the number one choice for cassette printing in Histology labs.

So if you are considering using barcode technology to identify and track patient specimens, remember that patient safety depends on legible barcodes that deliver high scan rates. And no other printing technology prints reliable barcodes like laser.

Get Laser Cassette Printing In Your Histology Lab

Learn more about General Data's LaserTrack cassette printers for histology, or contact us to request a demo - either in your lab or virtual.